Description

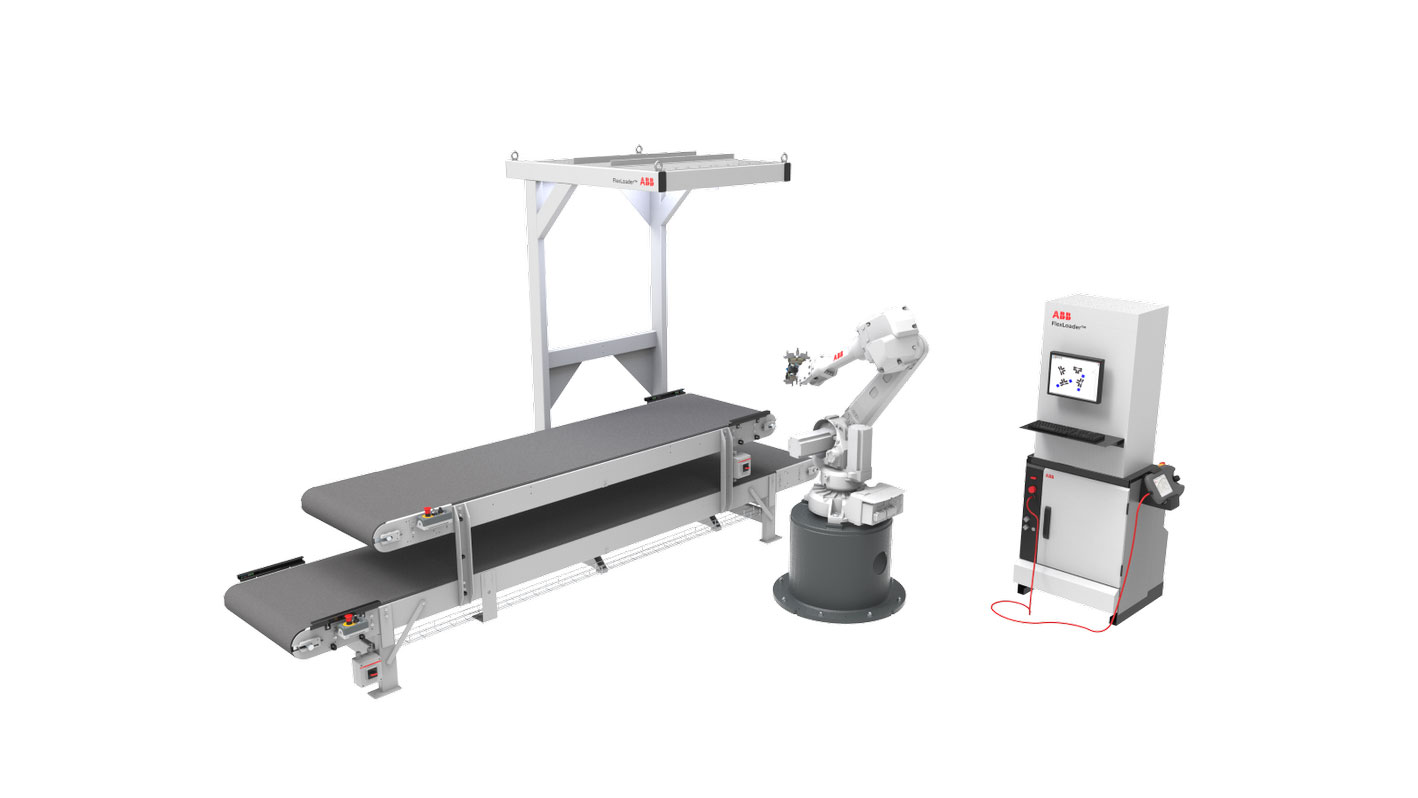

ABB FlexLoader Machine Tending Cells

Nortech works closely with ABB to supply modular machine tending solutions, like the FlexLoader system. FlexLoader automated machine tending cells are extremely user friendly and easy to program. In fact, they can be retooled without any specific robotics expertise.

Delivering simplicity through automation, FlexLoader M machine tending cells use digitalisation to take automated machine tending to a whole new level. Units are utilised in conjunction with powerful yet easy to use, integrated software. This enables every aspect of manufacturing machine tending to be managed in real-time, with order management, downtime reporting and fleet management just some of the processes that can be controlled at the touch of a button.

The feeding modules of our automated machine tending systems are also interchangeable, making them extremely easy to maintain, service and rebuild when needed. The result is a 60% increase in machine utilisation, a 30% larger workpiece buffer, and a highly configurable system for either 2D, semi-oriented 3D, or full random bin-picking.

FlexLoader™ Key Benefits

The FlexLoader machine tending cells are extremely user friendly and quick to program, even without specific robotics expertise. New workpieces can be introduced in minutes, making Batch Size One a reality.

Key benefits:

- Simplicity through automation:

The FlexLoader M machine tending cells are extremely user friendly and quick to program, even without specific robotics expertise. New workpieces can be introduced in minutes, making Batch Size One a reality. - Digitalization made easy:

Powerful yet easy to use Integrated software suit for machine tending operations with digitalization tools such as order management, downtime reporting & fleet management dashboards. - The power of modularity:

The feeding modules is interchangeable and makes it easy to maintain, service and rebuild the FlexLoader M cell when needed. - 60% Increase in machine utilization:

Robotic machine tending can prolong the production time with an extra unmanned shift with the possible to run multiple orders in one production run. - 30% bigger workpiece buffer:

The new modular design makes it easy to tailor the buffer to fit both your footprint and manufacturing needs. - Prepared for 2D & 3D vision:

Select the perfect match for your workpieces. FlexLoader M can easily be configurated for either 2D-, semi-oriented 3D- or full random bin-picking.

Why Choose Nortech?

Choosing Nortech as your manufacturing machine tending partner should be the first choice for facilities serving any industry. Working closely with manufacturer ABB, we are able to put the research and development of the latest automated machine tending tools and techniques first so you don’t have to.

Using automation, the latest machine tending cells and accompanying digitalisation tools, our automated machine tending systems are designed to suit your unique requirements both now and in the future. Our future-proof modular systems can be expanded as your operation or demand grows as a result.

Whatever the ambitions for your manufacturing machine tending cells, our qualified, fully equipped engineers and knowledgeable customer care team can support you every step of the way.

For further guidance on our automated machine tending solutions, please contact our team.