Description

Modular Metal Working Innovations from Euroma Group

Modular machining plays an important role in the optimised and tailored assembly of countless goods, with the use of modular tools like drilling units and tapping units providing complete solutions for more specific applications.

In partnership with advanced solutions specialist Euroma Group, we bring a series of modular machine systems to clients serving various industry sectors. Modular machining plays an important role in the optimised and tailored assembly of countless goods, with the use of modular tools like drilling units and tapping units providing complete solutions for more specific applications.

MPA

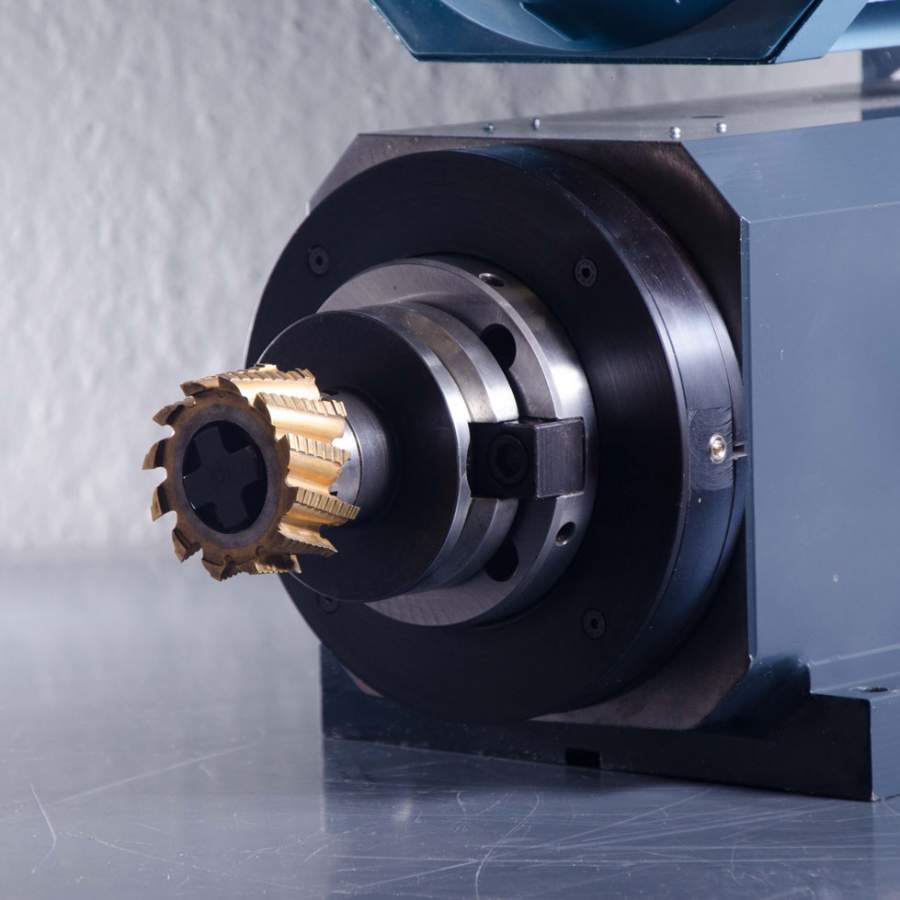

Development, production and distribution of multispindle heads, angle heads and rotating toolholders. Made in Italy excellence in the machine tool components sector. MPA has been producing angular heads, multi spindle heads and overgears since more than 45 years.

Unistand

- Clamping Fixtures

- Laser Welding Centres

- Planting and Assembly Stations

- Special Mechanical Realisation

Drillmatic

Electro-pneumatic CNC Quill Drilling Units

Electro-pneumatic drilling units by Drillmatic can perform any axial machining such as drilling, countersinking, reaming, counterboring, etc… Each unit has a rapid approach stroke and an operating stroke adjusted by a hydraulic shock absorber. Mechanical adjustments of stroke and feed speed are quick and accessible. The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

Units for combined drilling – tapping DTX units by Drillmatic are designed for combined drilling and tapping tools. Feed is managed by a pneumatic cylinder for drilling and by a lead screw for tapping. The switch between drilling and tapping is managed by a mechanical sensor. The dual-polarity standard motor allows to manage the two operations with the appropriate rotation speed. The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

Tapping units

Tapping units by Drillmatic are suitable for both rigid tapping with rolling taps, and external tapping with die. The operating stroke by means of the lead screw is easily adjustable thanks to a mechanical sensor. In the versions with pneumatic pre-stroke, the unit performs a fixed rapid approach. The lead screw is mounted in a coaxial position and immersed in an oil bath. A spring-loaded clutch system allows to preserve the lead screw in case of collision or extra torque. The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application.

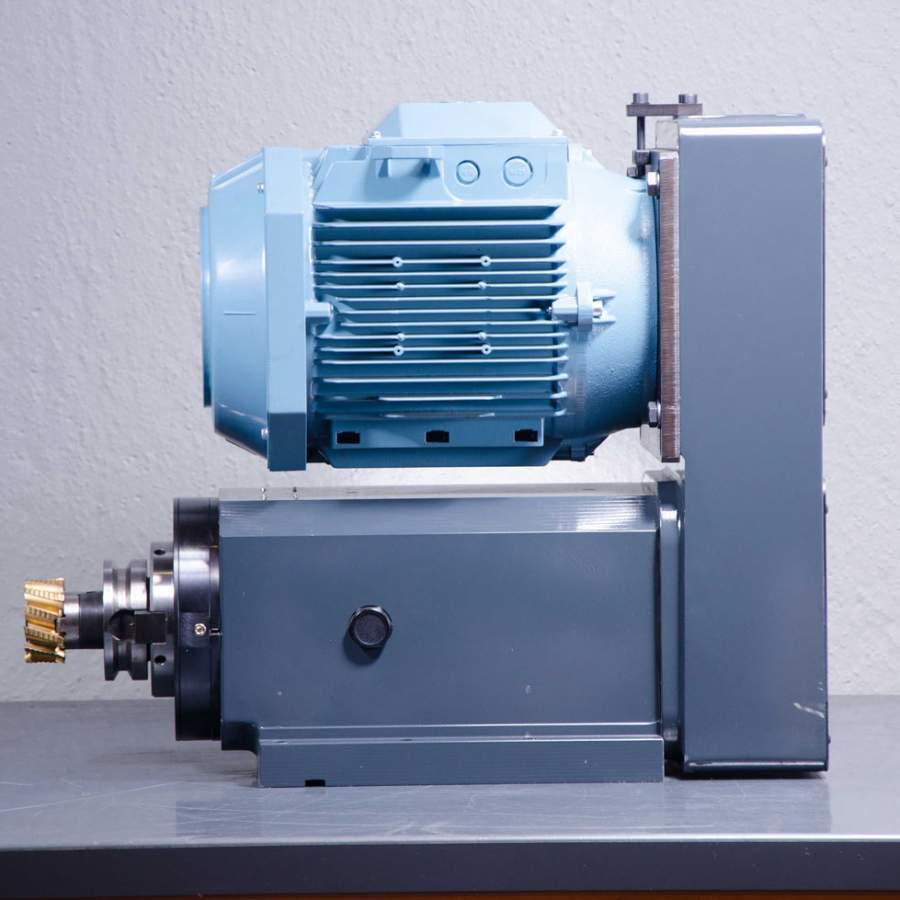

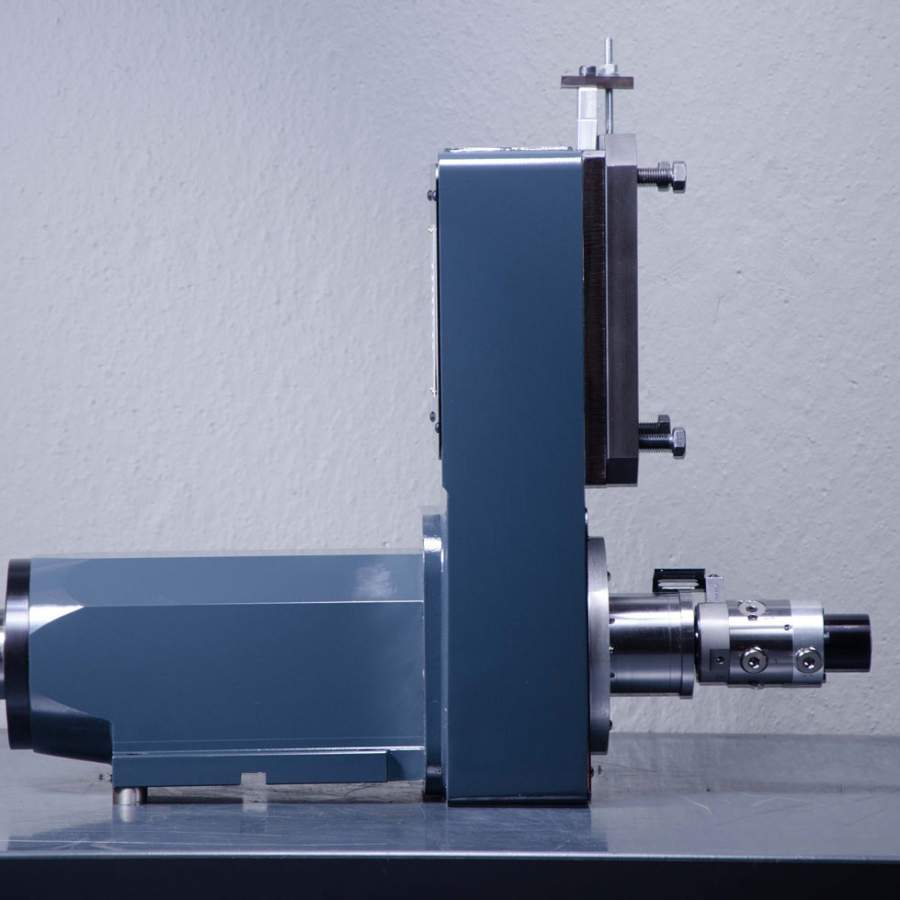

Machining spindles

Machining spindles by Drillmatic are suitable for both axial drilling and threading, as well as heavier radial machining such as milling, boring and cutting. The feed stroke is managed by the EX series CNC slide units. All spindles are configurable with ISO or HSK connections, in manual or automatic version. Depending on the machining to be performed and the speed of rotation, it is possible to provide the spindles with taper roller bearings or with angular contact. The great modularity and the different connection, motor and transmission configurations allow the customer to better adapt the unit to the application. Slide units The CNC slide units by Drillmatic have adjustable strokes, managed by rolling ball screw, and are suitable for the assembly of DX series spindles.

The carriage is moved by means of roller circulating rails and pads. Each slide has 3 standard mechanical sensors to manage production cycle and to set provision for centralized lubrication of pads and screw.

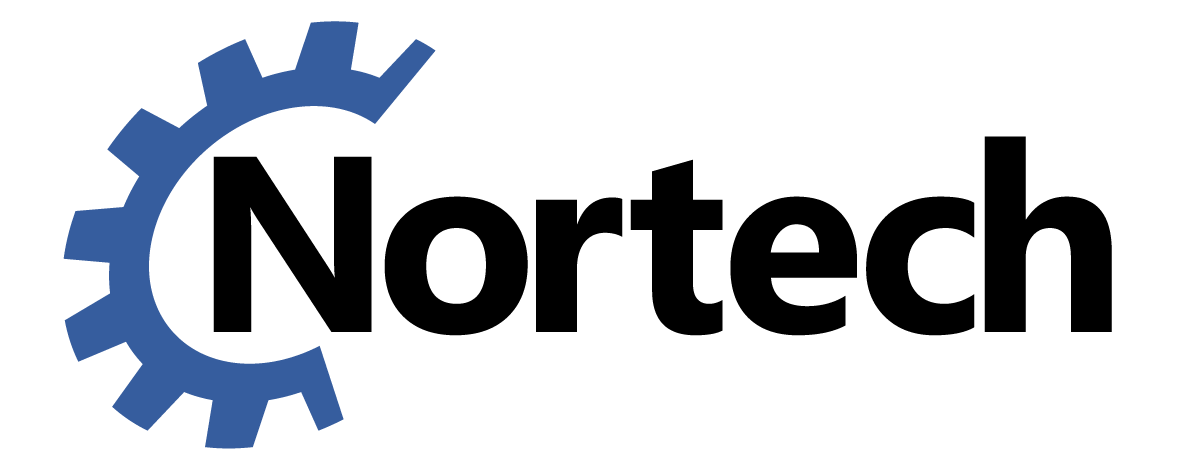

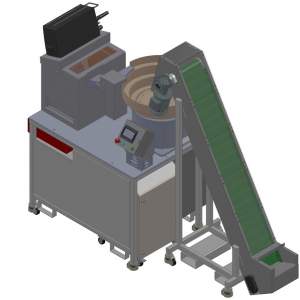

Rotary indexing tables

Drillmatic rotary indexing tables: with vertical axis or horizontal, with Hirth gears, or alternatively, also with conical pins.

The sturdy cast iron structure guarantees high rigidity and precision in order to perform any type of machining.

Accessories

Wide range of Drill Matic accessories for fastening and adjusting products: bases, fixed or adjustable columns, stop collars, adjustable supports and cross or parallel supports.

ISA Fork Heads, Ortogonal Type, Angular Heads, Extension Heads and Customised Heads

CMT Workholding Special, Other examples of special workholding equipment, Standard Work Holding