Description

Leak Test Machines

Increasing the quality of the products you provide to your own customers is a top priority for every organisation. There are many types of equipment that can be used to supply the quality assurance you need, including leak test machines.

Pressure Test Machines

Often referred to as ‘pressure testing’, leak testing gives you powerful insights into how much a product is leaking. The data gathered via leak testing enables you to specify acceptable leakage rates or leak limits for the affected items. Leak testing is undertaken using a variety of methods, from simple submersion (known as underwater leak testing) and pressure decay leak testing to more sophisticated, high speed, automated pressure testing.

Automate Your Leak Testing

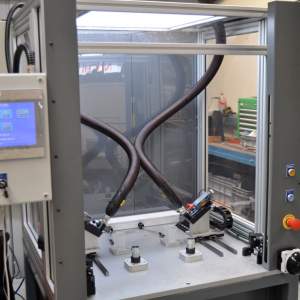

Using our pressure testing machines, you can automate the entire testing process as well as set limits and issue pass/fail markings without any manual intervention. We work with a number of manufacturers to deliver a selection of premium leak test machines to our clients, including Furness, Uson and Ateq.

Machines Designed for your Needs

Our pressure testing machines are accessible in a range of designs and capabilities, with selected leak testing models offering bench-mounted, high pressure fixtures as well as fully automatic systems. The pressure testing machines we supply can also be custom built to suit your exact application.

Leak Test Equipment Industries

Leak test equipment is commonly used in various industries, including:

- Manufacturing: To ensure that products like automotive parts, electronics, medical devices, or industrial equipment are free from leaks, which can be crucial for safety and quality.

- Oil and Gas: To test pipelines, valves, and other components for leaks, which is vital for preventing environmental damage and ensuring the integrity of the infrastructure.

- Aerospace: To test the seals and integrity of aircraft components and systems to guarantee safety and performance.

- Medical: To check the seal integrity of medical devices like syringes, catheters, or drug packaging, where even small leaks can have serious consequences.

- Pharmaceutical: To ensure the sealing of pharmaceutical containers and packages to prevent contamination and maintain product quality.

- Plumbing: To detect leaks in water supply and gas pipelines to conserve resources and prevent hazards.

- Automotive industry:

The use of leak testing is particularly prevalent in automotive operations including

- Engine assemblies

- Cylinder blocks and heads

- Timing and cam covers

- Gearbox and clutch housing

- Manifolds

- Fuel tanks

- Battery cooling systems

These are just some of the components that can be verified automatically using our leak test machines

Leak test equipment plays a critical role in quality control and safety across many different industries, where ensuring that products or systems are leak-free is essential for their proper functioning and to avoid potential risks or environmental harm.

Why Choose Nortech?

Why choose Nortech for your leak test systems

Nortech is your route to precise leak testing equipment. Our supply of standard and bespoke pressure testing machines means you can access the equipment needed to meet your unique requirements. Our leak test machines can be easily incorporated into both automatic or manual lines to ensure economical and quantifiable pressure testing across all components.

Extended support for pressure test equipment

Our service doesn’t end when your pressure testing machines are designed, developed and installed. Our aftercare service is second to none, with our highly experienced engineers on hand to assist with servicing, production support and spares amongst other services.

With a reputation for designing and supplying high quality, comprehensive solutions, we’re here for you for the long term. Product research and development is an ongoing commitment in-house and among our strategic partners whilst the highest standard of customer care is guaranteed throughout your journey.

For additional information on why you should work with us when commissioning your first or next leak test machine, get in touch today.