Description

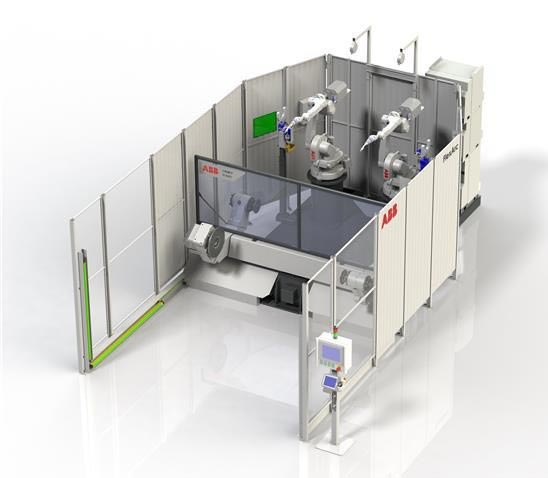

Our Robotic Welding Cells

In partnership with ABB, we provide articulated robotic welding cell configurations to assist with:

- Arc Welding

- Laser welding

- Spot welding

The cells consist of the articulated robot arm, positioner, controller, safety PLC, push buttons, cell guarding, viewing windows and access doors.

ABB IRB Robot & Controller

- Superior motion performance

- Collision detection software

- Offline programming

- Highly accurate calibration

ABB IRBP Positioner

The IRBP Positioner holds the workpiece in place and offers dynamic motion in coordination with the robotic arm, to a tight tolerance of 0.05mm and with a load capacity up to 5000kg.

Video Brochure

Watch the video showing our ABB Robot Portfolio here:

Custom Configurations

Custom Configurations

Cells are complete systems with a flexible, modular design for custom configuration. We optimise to fit into your floor space and processes.

- Choose welding type: Arc, Laser or Spot welding

- Choose the required reach of the robotic arm: <1.8m, 1.8-2.55m, >2.55m

- Choose the maximum payload: from <7kg to >225kg

We will help & guide you through every step of the design process. If you’re unsure of your exact requirements please don’t hesitate to contact us. We’re happy to talk through the intended product design and manufacture process and construct a requirements list together.#

Easy to Program and Service

We provide training for your team to program our robotic welding cells offline or online.

ABB Welding robots use simple and intuitive programming software (RobotStudio) to determine the weld path accurately.

Service the weld torch without entering the cell at all. When needed, the arm turns towards the Torch Service Window, improving productivity and uptime.

IRB Variants

IRB range from ABB

The IRB range of ABB articulated robots offers a vast selection of variants, catering to as many end-user applications as possible. Find the latest information on articulated robots available on the ABB website.

Superior Safety

All robot welding cells are equipped with safety features, including:

- Safety PLC

- Impact-resistant panelling

- Door safety sensors

- Floor scanner

- Object collision detection

- Auto-path recovery

- ANSI/RIA R15.06-2012 compliance

Our partnership with ABB

ABB Robotic Welding Cells

With the valuable support and partnership of ABB Robotic Welding Cells, we can provide comprehensive turn-key solutions. Nortech can supply a standard ABB robotic welding cell, or create a bespoke robotic welding cell tailored to your production needs.

We tend to find that customers who choose a Standard Robotic welding cell later request a bespoke adjustment. Talk to us before making your decision, and we will use our experience and expertise to advise you on the best option.

Benefits of Robotic Welding

In robotic welding, robots take over the welding work automatically following a program that can be adjusted for different projects.

Using articulated robots makes the welding process more precise, faster, and safer. They can reach tight spots and do complex welds. This saves time in manufacturing and makes things more flexible